XZB500 mask packing machine

Introduction

Safety: The moving parts below the machine is covered by protection shield to guarantee the safety

Easy operation: Central controlled by PLC, equipped with touching screen HMI, easy to operate like changing the parameter. All error info will be displayed. Sealing temperature of each seal is controlled independently, can be applied for multiple kinds of packing material. The sealing is beautiful and firm, can be set manually.

Unique Design: Main control electrical circuit is control by frequency and displayed by touching screen, excellent human-machine interface makes operation easy and convenient. The whole machine is controlled by double frequency with wide frequency rate, which enlarge the speed range and realize the stepless speed change.Packing speed can be set according to the speed of the production line, perfect match with each other.Once the lengths of film and bag is set, high-sensitive sensor will automatically control and follow the packing. The length of bag will be accurate and no manual adjust is requiredThe equipped coding machine will be easy to print the date and code, running and same pace with packing.

Feed Mode:Manually feed the equipment into the feed conveyor chain

Product :mask、biscuit、bread、pill、diaper etc.

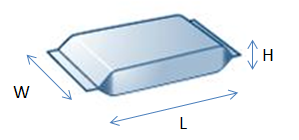

Size:LxWxH = (60- ) x (30-150) x (5-50)mm

(For other on-standard size,please inform in advancefor new design)

Wrapping Speed:35-150 pcs/min Double-blade (Speed depends on the size of the products)

Film Width:65-400mm

Film Material:OPP/CPP、PT/PE、KOP/CPP、ALU-FOIL

(need to be informed In advance)

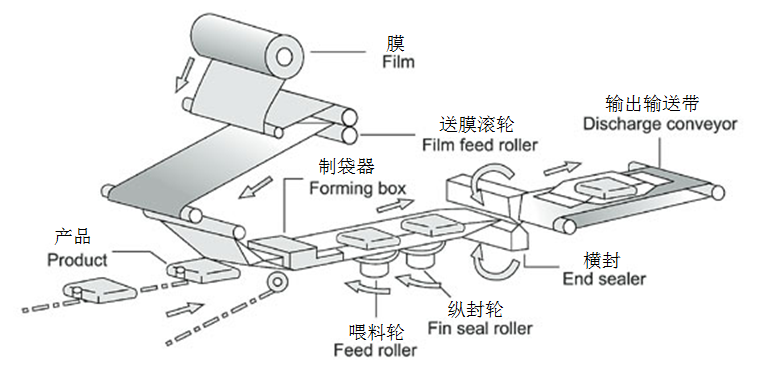

Wording Process and Function

1、 Feeder will place and convey products to the input conveyor of flow wrapper manually, then product will move forwardpushed by shifting fork

2、 Film will be formed by forming box after film feed roller, and product will be sent to the formed film by feed roller .

3、 Films with products will be formed to be in a tubular shape after fin seal roller

4、 The films with products will be cut into finished packed products by end sealer

5、 The finished products will be conveyed out by discharge conveyor

Layout

Dimension: LxWxH = 4000×950×1600 mm

Weight: 630kg

Direction: When operator is facing the machines,the machine runs from left to right