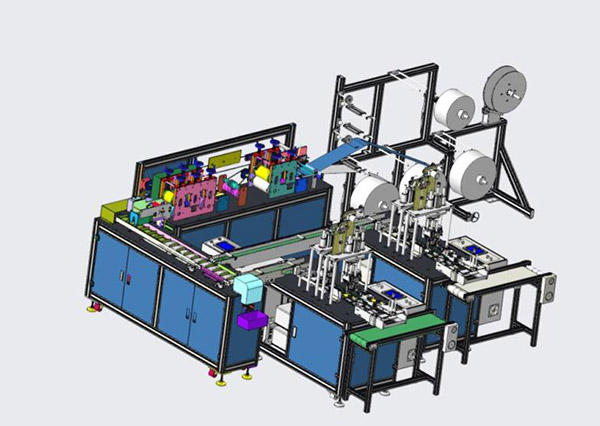

One-to-two full-automatic facial mask machine

Introduction

(1)One-to-two full-automatic facial mask machine adopts PLC control system to make material feeding from coil, folding and pressing, nose bridge tendon feeding, ultrasonic welding, mask forming, mask cutting, ear band feeding and welding, finished the blanking , and the entire production process is automated, continuous and efficient.

(2)Intelligent control platform, convenient and quick setting of human-machine interface parameters, simple operation and easy learning, one person can operate multiple units to work at the same time.

(3)The production stability is high, the failure rate is low, and the floor area is small. The two output lines simultaneously increase the output significantly.

(4)When the coil material and the bridge of the nose are out of material, the photoelectricity (optical fiber) detects the raw materials and automatically shuts down to avoid waste.

(5)The earband is automatically welded by ultrasonic.

(6)The quantity of finished product stacking parameters can be set to meet different packaging needs.

(1).Dimensions:(L)6800(W) X 4800(W)X1860(H)mm

(2).Power:equipment220V±5%,50Hz,rated power 12KW

(3). Compressed air:5-6kg/cm²,usage flow around 300L/min

(4).Environment:temperature 10-35℃,humidity 5-35%HR, without flammable and corrosive gases,dust free(no less than 100,000 degrees of cleanliness)

|

Production Speed |

100-120piece/min(one-to-two) |

|

Mask size |

(L)175mm X (W)95mm |

|

Non-woven fabric width |

200mm |

|

Realated materials |

Non-woven fabric,filter paper,bridge of nose,ear band |

|

Mask structure |

Earloop type |

|

Stacking number |

Adjusted |

|

Equipment power |

12KW |

|

Ultrasonic frequency |

20KHz |

|

Compressed air |

0.5-0.8 MPa |

|

Voltage |

220V,50Hz |

|

Dimensions |

(L)6800X(W)4800X(H)1860mm |

|

Equipment weight |

Around 2000kg |